Exploring Cost Efficiency in Low Cost Injection Molding at 2025 China Import and Export Fair

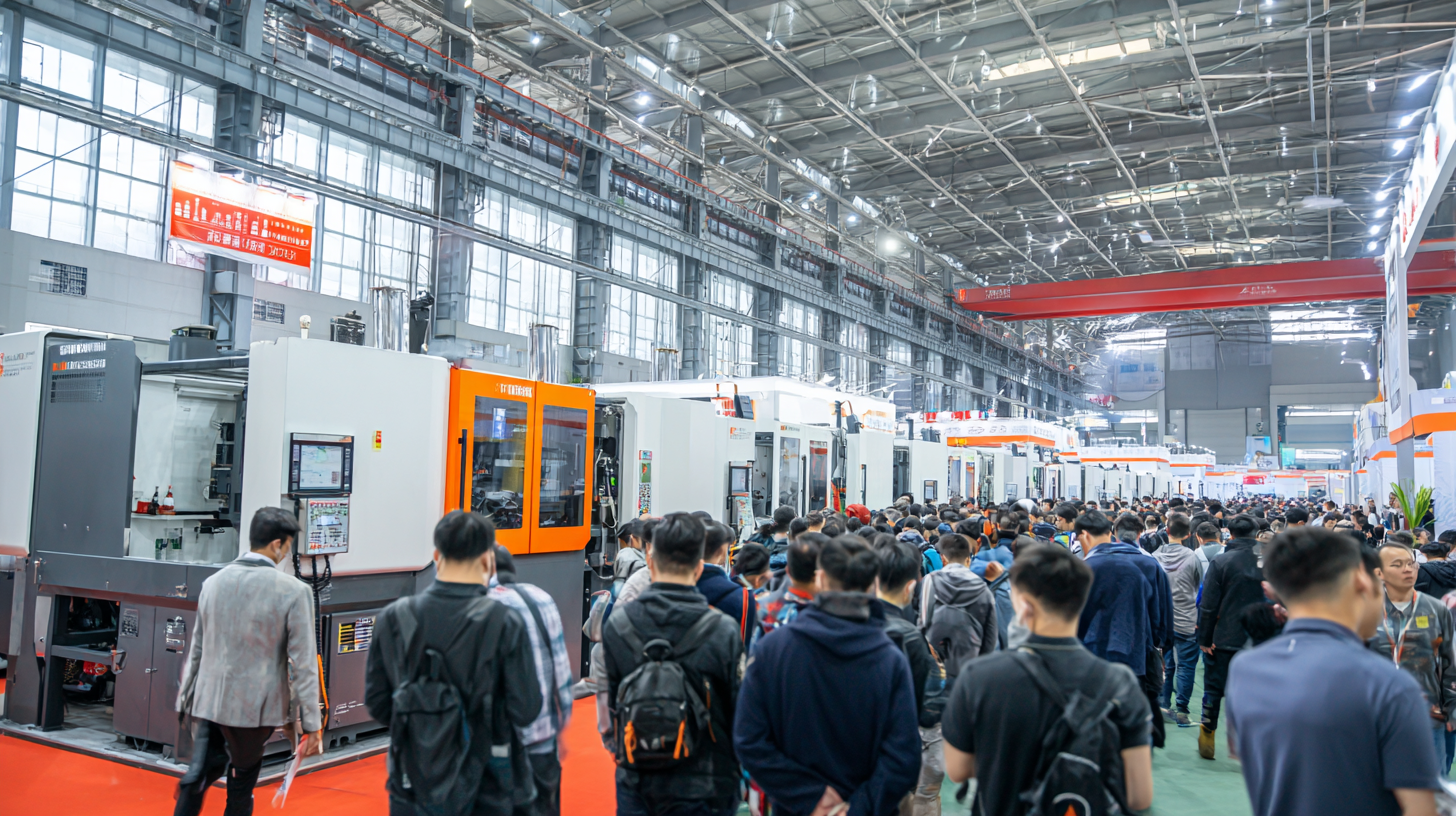

The 2025 China Import and Export Fair, also known as the Canton Fair, presents a unique opportunity to delve into the advancements and cost efficiency of low cost injection molding.

The global injection molding market is projected to reach approximately $348.1 billion by 2025, with low-cost solutions driving a significant portion of this growth.

According to a recent study by MarketsandMarkets, cost efficiency is crucial as manufacturers strive to enhance production capabilities while reducing expenditures.

The shift towards low cost injection molding technologies not only supports competitive pricing but also promotes sustainable manufacturing practices by optimizing material usage and energy consumption.

As China's manufacturing landscape evolves, the focus on cost-effective methods in injection molding will be integral for companies aiming to maintain market relevance, particularly in an increasingly competitive global arena.

The global injection molding market is projected to reach approximately $348.1 billion by 2025, with low-cost solutions driving a significant portion of this growth.

According to a recent study by MarketsandMarkets, cost efficiency is crucial as manufacturers strive to enhance production capabilities while reducing expenditures.

The shift towards low cost injection molding technologies not only supports competitive pricing but also promotes sustainable manufacturing practices by optimizing material usage and energy consumption.

As China's manufacturing landscape evolves, the focus on cost-effective methods in injection molding will be integral for companies aiming to maintain market relevance, particularly in an increasingly competitive global arena.

Exploring Innovations in Low-Cost Injection Molding Technologies at the 2025 China Import and Export Fair

The 2025 China Import and Export Fair will serve as a pivotal platform for showcasing the latest innovations in low-cost injection molding technologies. As the demand for cost-efficient manufacturing solutions continues to rise, many exhibitors will present groundbreaking techniques and materials that promise to reduce production costs while maintaining high-quality standards. Attendees will have the opportunity to explore advancements that utilize sustainable resources and streamlined processes, giving businesses the tools they need to enhance their profitability and competitive edge in the market.

Tip: When exploring new technologies at trade fairs, it is essential to engage directly with the developers and industry experts. Ask questions about the practical applications, scalability, and potential challenges of new solutions to get a comprehensive understanding of how they can benefit your operations.

Moreover, the fair will highlight collaborations between technology providers and manufacturers, showcasing how these partnerships are driving innovation in the injection molding sector. As companies continually seek to optimize their production lines, exploring these collaborative efforts can provide insights into effective strategies for implementing low-cost techniques.

Tip: Stay proactive by collecting literature and digital resources during the fair. This will allow you to compare different technologies and make informed decisions about which innovations align best with your business objectives.

Analyzing Market Trends and Demands for Injection Molded Products in 2025

In the dynamic landscape of 2025, the injection molded products market is witnessing a significant shift towards customization and personalization. As consumer preferences evolve, there is a burgeoning demand for tailored solutions in pumps and dispensers, prompting manufacturers to innovate. This trend underscores the importance of meeting unique customer needs, which not only enhances user experience but also drives competitive advantage in the fast-paced market.

Moreover, projections indicate remarkable growth in various sectors, including the automotive plastics market and smart cabin technologies, further fueling the demand for customized injection molded components. The ongoing transition towards electric vehicles and intelligent cockpit solutions presents opportunities for suppliers that can adapt quickly to market changes. As companies seek to optimize their production processes for cost efficiency, the focus on unique and specialized injection molded products will be crucial for capturing market share in the years to come.

Cost Efficiency in Low Cost Injection Molding - Market Trends 2025

Cost-Benefit Analysis of Low-Cost Injection Molding Techniques in the Current Market

The current market for low-cost injection molding is witnessing significant transformations, driven by the increasing demand for cost-effective manufacturing solutions. A cost-benefit analysis of low-cost injection molding techniques reveals that businesses are striving to optimize production efficiency while minimizing expenses. Techniques such as using C6-LLDPE, which is expected to grow from 18,835.01 metric tons in 2025 to 25,094.28 metric tons by 2033 at a CAGR of 3.7%, demonstrate the shift towards materials that offer affordable production without compromising quality.

Furthermore, the pump and dispenser market is another area where cost efficiency is essential. Valued at $17.79 billion in 2025, it is projected to reach $23.94 billion by 2032, showcasing an escalating demand for efficient technologies that streamline processes. Simultaneously, the LIM and LSR injection molding machines, with a projected increase from $159.5 million in 2024 to $283.83 million by 2032 at a 7.47% growth rate, highlight the industry's pivot towards innovative molding techniques that enhance both performance and cost-effectiveness. As manufacturers look for ways to adapt to evolving market conditions, the importance of cost-benefit analyses in guiding investment decisions becomes increasingly apparent.

Evaluating the Role of Sustainability in Cost-Effective Injection Molding Solutions

The role of sustainability in cost-effective injection molding solutions is increasingly becoming a focal point for manufacturers at the 2025 China Import and Export Fair. As the industry faces growing pressures to minimize environmental impact, companies are seeking innovative ways to integrate eco-friendly practices without sacrificing cost efficiency. Utilizing recyclable materials and energy-efficient machinery not only reduces waste but also lowers production costs over time, highlighting a lucrative path for businesses aiming for both profitability and sustainability.

Moreover, advancements in technology are facilitating the shift towards sustainable practices in injection molding. For instance, the introduction of biodegradable polymers and hybrid molding processes enhances the feasibility of environmentally responsible production methods. Manufacturers are finding that by investing in these sustainable solutions, they can achieve competitive advantages while responding to consumer demand for more responsible products. This dual focus on cost efficiency and sustainability is not only a trend but a necessary evolution in the injection molding industry, paving the way for a future that balances economic viability with environmental stewardship.

Identifying Key Players and Emerging Startups in Low-Cost Injection Molding Industry at the Fair

At the 2025 China Import and Export Fair, the spotlight will be on the low-cost injection molding industry, with a particular emphasis on identifying key players and emerging startups. This event will serve as a significant platform for showcasing innovations and cost-efficient solutions that cater to the growing demand for affordable manufacturing options. As industries worldwide seek to streamline production without compromising quality, the presence of startups that leverage cutting-edge technology in injection molding will likely attract considerable attention.

Emerging startups are expected to present unique approaches that differentiate them from established players in the low-cost injection molding market. These companies are poised to disrupt traditional manufacturing models by offering more agile and adaptable solutions tailored to specific customer needs. With the potential for substantial price increases, as highlighted in recent financial analyses, investors will be keen to observe which startups emerge as the leading innovators at the fair. This dynamic environment will not only highlight the competitiveness of the low-cost injection molding sector but also signal a transformative shift as new market entrants harness efficiencies that promise higher returns.

Related Posts

-

5 Essential Tips for Sourcing Small Run Plastic Injection Molding: A Global Buyer’s Guide

-

Maximizing Your Investment with Exceptional After Sales Service in Low Volume Injection Moulding

-

Innovative Strategies for Mastering Injection Molding in the 2025 Industry Landscape

-

Ultimate Guide to Choosing the Right Injection Machine for Your Manufacturing Needs

-

How to Optimize Your Plastic Injection Molding Process for Maximum Efficiency

-

How to Maximize Efficiency in Small Volume Injection Molding: Industry Insights and Best Practices