Advancing Plastic Injection Molding with Mantle’s 3D Tool Printing Technology

Elite Mold & Engineering is proud to introduce Mantle’s cutting-edge metal 3D printing technology for toolmaking into our manufacturing process. This game-changing innovation reinforces our commitment to delivering our clients high-quality, precision-engineered plastic injection molding solutions.

Revolutionizing Mold Production with Mantle’s 3D Tool Printing Technology

By integrating Mantle’s state-of-the-art 3D printing system, we are transforming the way we design and manufacture molds. This advanced technology allows us to produce precise, high-performance molds that meet the most demanding specifications while reducing lead times, increasing efficiency, and lowering overall costs. With this addition, our customers can expect faster turnaround times and superior-quality plastic injection molded parts.

HOW it works:

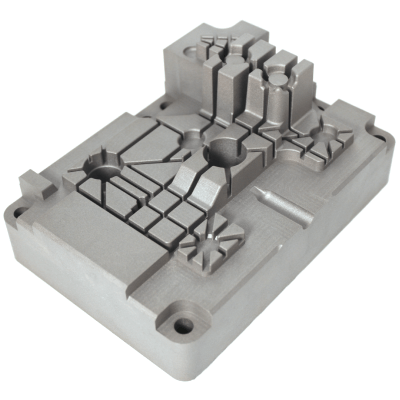

Mantle’s automated toolmaking system brings together CNC machining, 3D printing, industry-standard tool steels, and advanced software to produce tooling components with the surface finish, accuracy, and steel properties required to make the world’s best products.

Key Benefits of Mantle’s 3D Mold Printing Technology

- Faster Lead Times: Mantle’s technology automates the most time-consuming and expensive parts of the tool build, enabling complex inserts to be produced rapidly.

- Cost Efficiency: By eliminating secondary processes like sinker EDM and excess programming, we streamline operations while offering more competitive pricing without sacrificing quality.

- Advanced Design Flexibility: Mantle is a hybrid additive and subtractive technology. This approach enables the production of geometries that would be challenging to achieve with traditional toolmaking processes, such as conformal cooling and deep thin ribs.

- Superior Durability: Molds produced using Mantle’s system are built with durable, industry-standard tool steels H13 and 420 stainless steel, providing durability and tool life into the millions of cycles.

- Visit Mantle’s website at https://mantle3d.com/ to learn more about the various benefits of utilizing their new technology.

Commitment to Innovation in Plastic Injection Molding

At Elite Mold & Engineering, we continually invest in cutting-edge technology to enhance our plastic injection molding services. By adopting Mantle’s 3D tool printing technology, we reaffirm our dedication to delivering high-quality products, reduced lead times, and cost-effective solutions for our clients.

Discover the Mantle Advantage for Your Next Project

We invite you to explore how this groundbreaking technology can optimize your manufacturing process. Contact us today to learn more about our enhanced capabilities and how we can bring your vision to life.