Global Success of Medical Injection Molding from China Driven by Quality Enhancement

The global medical injection molding industry has witnessed significant growth in recent years, with China emerging as a leading player due to its commitment to quality enhancement. According to a report by Research and Markets, the global market for medical injection molding was valued at approximately $4.4 billion in 2021 and is projected to reach around $6.1 billion by 2026, growing at a CAGR of 6.5%. This growth is largely attributed to the increasing demand for medical devices and components, particularly as the healthcare sector continues to expand. China's advanced manufacturing capabilities, coupled with stringent quality control measures, have positioned its factories among the top exporters globally, ensuring that they meet the rigorous standards expected in the medical field. As a result, the country's medical injection molding sector is not only thriving domestically but also making a significant impact on the international stage, contributing to advancements in medical technology and patient care.

Types of Medical Injection Molding Products and Their Unique Characteristics

Medical injection molding has become a cornerstone of the healthcare industry, with a variety of products that cater to diverse medical needs. The types of products manufactured through this process range from syringes and IV bags to complex surgical instruments and implants. Each of these categories has unique characteristics that enhance their functionality and patient safety. For instance, syringes made through high-precision injection molding are designed to minimize dead space, ensuring accurate dosages, while IV bags often utilize materials that enhance their durability and compatibility with various medications.

The global market for medical injection molding is projected to reach approximately $20 billion by 2025, driven largely by advancements in polymer technologies and manufacturing techniques. According to a report by MarketsandMarkets, the demand for customized solutions in medical devices is a significant factor propelling this growth. Products such as single-use medical devices, which are fabricated to minimize cross-contamination, illustrate how injection molding can create highly specific and regulatory-compliant items. The push for quality enhancements not only addresses safety concerns but also aligns with the growing trends of sustainability and cost-efficiency in the medical sector.

Applications of Medical Injection Molded Products in Healthcare and Pharmaceuticals

The applications of medical injection molded products in healthcare and pharmaceuticals are rapidly expanding, driven by advancements in material quality and manufacturing techniques. As the global population ages, the demand for innovative medical devices increases, necessitating high-performance plastics that can meet stringent regulatory standards. Medical injection molding has become a key process in producing everything from syringe components to complex diagnostic devices. With the market for medical injection molded plastics projected to grow significantly, reaching up to USD 38.18 billion by 2033, manufacturers are investing in technologies that enhance the quality and reliability of these products.

In particular, cyclic olefin polymers (COP) are gaining traction for their excellent properties, including chemical resistance and low moisture absorption. This positions them as ideal candidates for critical applications in drug delivery systems and sterile packaging. As the healthcare industry continues to emphasize the importance of patient safety and product efficacy, the integration of advanced materials like COP and the optimization of injection molding processes will play a crucial role in future innovations. Moreover, with the rise of sustainability concerns, the development of bio-based compounds for medical applications is paving the way for greener manufacturing practices in this essential sector.

Quality Standards in Medical Injection Molding: Ensuring Safety and Effectiveness

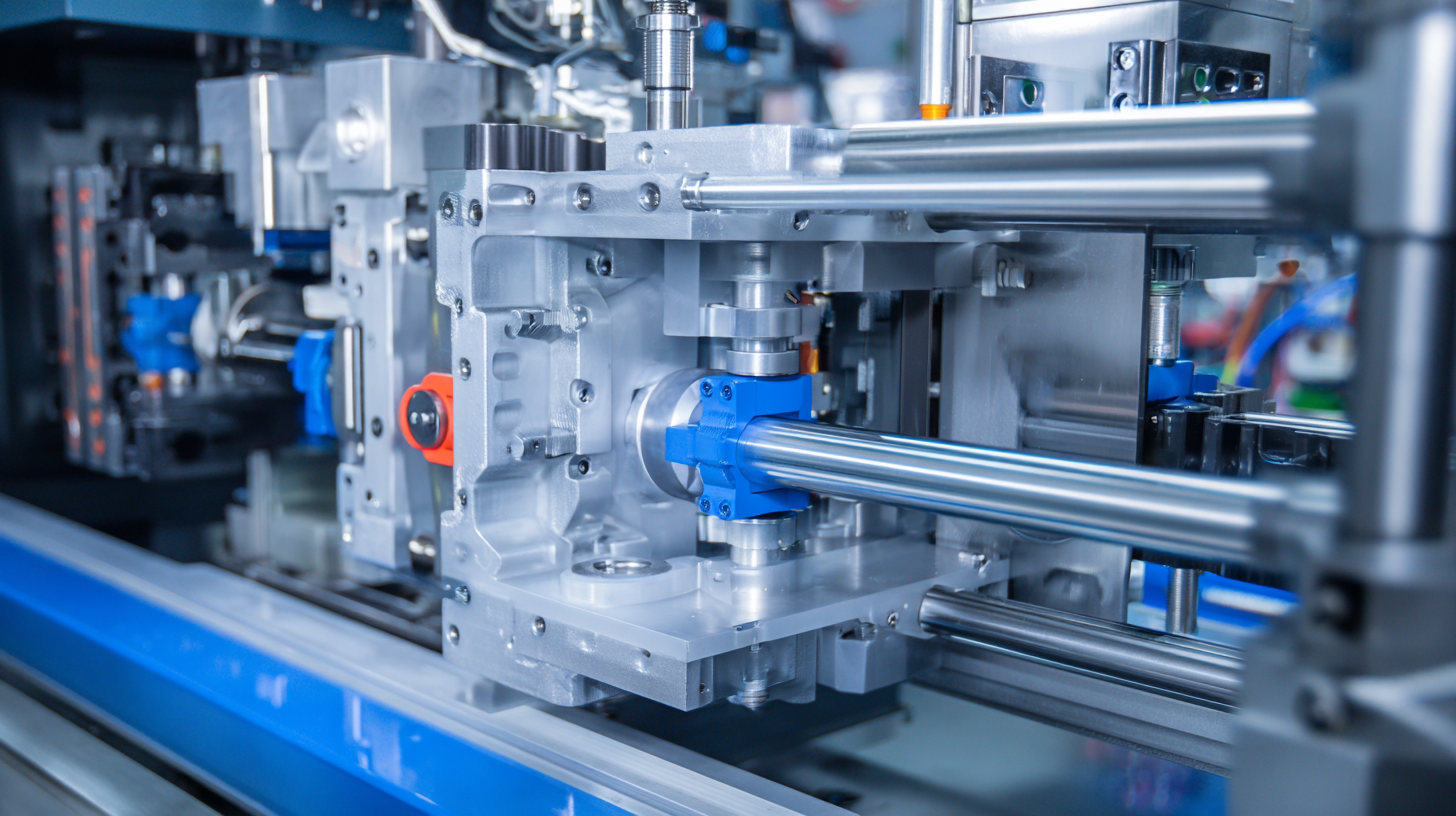

In the rapidly evolving landscape of medical manufacturing, the quality standards in medical injection molding have become paramount in ensuring both safety and effectiveness. With the increasing demand for high-performance medical devices, manufacturers in China have stepped up their game, implementing rigorous quality control processes that adhere to international regulations. This commitment to quality not only enhances the reliability of medical products but also builds trust with healthcare providers and patients worldwide.

One of the key aspects of quality standards in medical injection molding is the use of advanced materials and technologies. Manufacturers are now embracing innovative manufacturing techniques, such as automation and precision tooling, to minimize defects and ensure consistent product performance. Additionally, thorough testing and validation processes are integral to the production cycle, allowing for early identification of potential issues, thereby safeguarding patient safety. By prioritizing quality, Chinese manufacturers have established themselves as leaders in the global market, demonstrating that excellence in medical injection molding is not just about meeting standards, but about exceeding them.

Market Trends: Growth Projections for China's Medical Injection Molding Industry

The medical injection molding industry in China is witnessing remarkable growth, driven by enhanced quality standards and innovative practices. As the global plastic processing machinery market is projected to reach a value of $22.66 billion by 2024, this surge indicates a robust demand for advanced manufacturing technologies within the medical sector. The market for plastic injection molding machines catering to the MedTech sector is estimated to reach $2.18 billion by 2024, with a compound annual growth rate (CAGR) of 4.6% anticipated from 2025 to 2034.

To thrive in this competitive landscape, manufacturers should focus on adopting cutting-edge technologies and automated solutions. Incorporating smart manufacturing processes can not only enhance efficiency but also significantly improve product quality. It's essential to keep abreast of industry regulations and standards to ensure compliance and foster trust among stakeholders.

Additionally, companies should consider investing in research and development to innovate products that meet the evolving needs of an aging population in markets like the US and Europe. Emphasizing sustainable practices in production will not only contribute to environmental conservation but also appeal to a growing market segment that prioritizes eco-friendly products.

Comparative Analysis: China vs. Global Players in Medical Injection Molding Quality

The medical injection molding sector is witnessing significant developments, particularly in China, which has become a formidable player on the global stage. The global injection molding market is projected to grow to USD 38.01 billion by 2033, reflecting a CAGR of 5.94%. This growth is substantially driven by the increasing demand for medical devices that require high-precision manufacturing processes. China's focus on quality enhancement in medical injection molding has allowed it to compete effectively with established global players, where investments in advanced technologies and stringent quality control measures are paving the way for superior products.

**Tip:** When evaluating different suppliers in the medical injection molding market, consider their history of quality improvements and certifications, as these indicators can significantly influence the reliability of their products.

Furthermore, the rise in healthcare expenditure is expected to boost the demand for plastic injection molding, with the sector projected to grow. The global medical injection molding machine market, valued at USD 1.81 billion in 2022, is expected to expand at a CAGR of 4.7% from 2023. As China elevates its standards and production capabilities, it is crucial for businesses worldwide to stay informed about this competitive landscape to leverage opportunities effectively.

**Tip:** Staying updated on market trends and forecasts can help businesses make informed decisions regarding investments in injection molding technology and supplier selection.

Global Success of Medical Injection Molding from China Driven by Quality Enhancement - Comparative Analysis: China vs. Global Players in Medical Injection Molding Quality

| Region | Quality Score (0-100) | Production Capacity (Units/Month) | Compliance Certifications | Average Lead Time (Days) |

|---|---|---|---|---|

| China | 90 | 500,000 | ISO 13485, CE | 20 |

| North America | 85 | 300,000 | ISO 13485, FDA | 30 |

| Europe | 88 | 400,000 | ISO 13485, CE | 25 |

| Asia-Pacific (excluding China) | 80 | 200,000 | ISO 13485, TGA | 40 |

| Latin America | 78 | 150,000 | ISO 13485 | 50 |