Innovative Strategies for Mastering Injection Molding in the 2025 Industry Landscape

As we look towards the 2025 industry landscape, the injection molding process remains a cornerstone of modern manufacturing, shaping the production of diverse components across numerous sectors. According to a recent report by MarketsandMarkets, the global injection molding market is projected to reach over $300 billion by 2025, driven by increasing demand for lightweight and high-performance materials in automotive, consumer goods, and healthcare applications. This surge underscores the necessity for innovative strategies that enhance efficiency, reduce costs, and improve the quality of molded products. The transition to smarter manufacturing approaches, combined with advancements in materials science and automation, is set to redefine how businesses leverage injection molding technology. Emphasizing agility and sustainability will be crucial as manufacturers navigate the complexities of the evolving market and align with shifting consumer preferences.

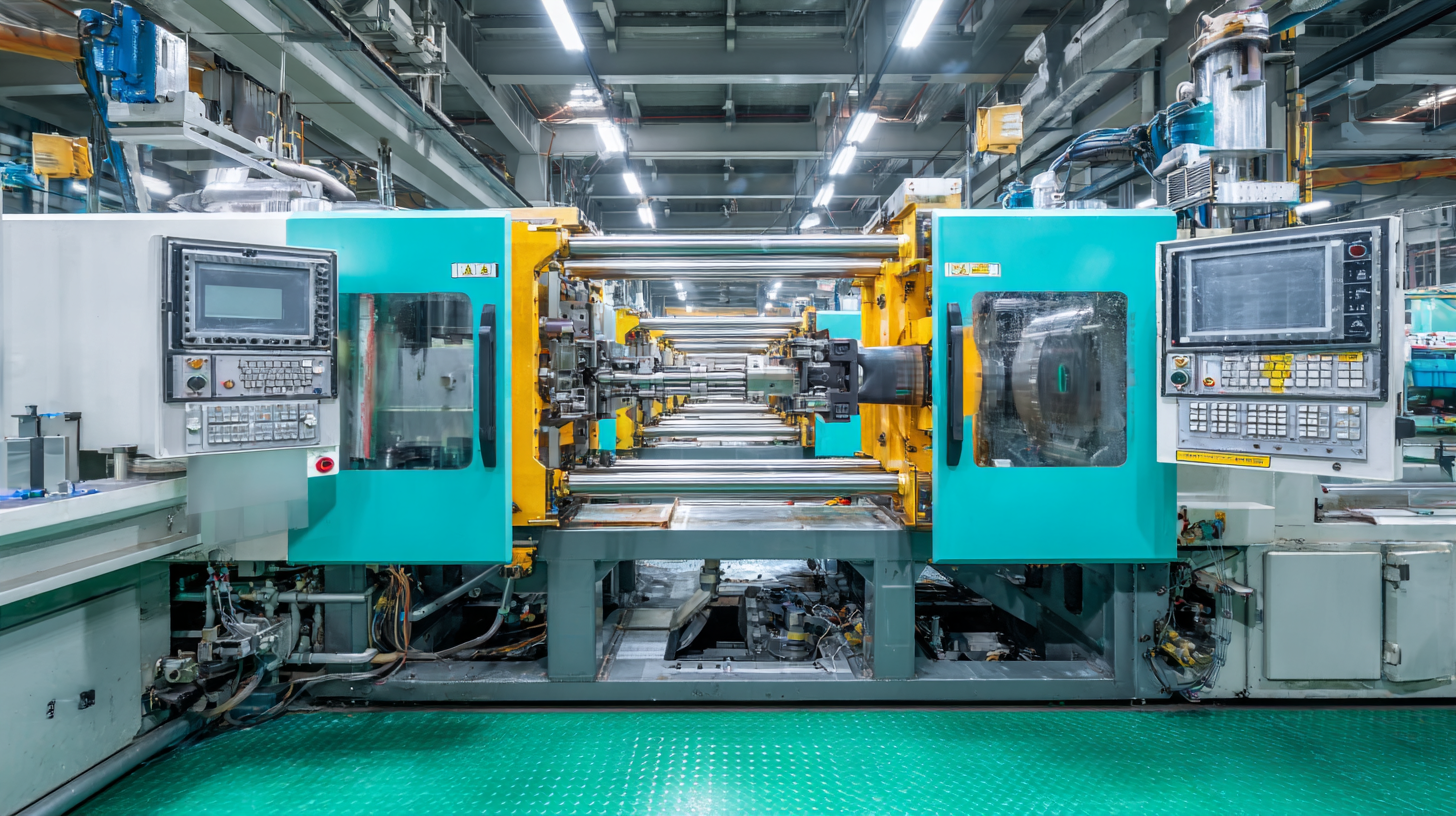

Emerging Technologies Revolutionizing Injection Molding for 2025

As we look towards 2025, the injection molding industry is on the brink of a technological revolution, significantly influenced by emerging technologies. According to a report by MarketsandMarkets, the global injection molding market is projected to reach $370 billion by 2025, driven by advancements in material science and automation. These innovations are not just enhancing production efficiency but are also paving the way for more sustainable practices.

One of the most notable emerging technologies is the incorporation of artificial intelligence and machine learning into the injection molding process. These technologies enable real-time monitoring and predictive maintenance, which can reduce downtime by up to 30%, as reported by Deloitte. Additionally, new materials such as bio-resins are gaining traction, catering to the growing demand for sustainable and eco-friendly solutions. As these technologies become more accessible, manufacturers will be better equipped to optimize their processes, reduce costs, and improve product quality, ultimately transforming the industry landscape in the coming years.

Innovative Strategies for Mastering Injection Molding in the 2025 Industry Landscape

This chart represents the projected advancements in various technologies impacting the injection molding industry by 2025, highlighting key areas of focus for innovation and strategy development.

Sustainable Practices in Injection Molding: Balancing Quality and Environmental Impact

As the injection molding industry evolves, sustainable practices are becoming paramount to ensure both quality products and minimal environmental impact. According to a report from the Global Plastics Alliance, approximately 300 million tons of plastic are produced annually, with a significant portion resulting from traditional manufacturing methods that contribute to ecological degradation. To counter this, many manufacturers are shifting to bio-based and recyclable materials that not only reduce dependency on fossil fuels but also minimize waste. The adoption of these materials in injection molding can significantly lower the carbon footprint, with studies showing potential reductions of up to 70% in lifecycle emissions when transitioning to sustainable alternatives.

Moreover, implementing advanced technologies such as energy-efficient molding machines and optimization software can further enhance sustainability efforts. The National Molding Association reports that the use of servo-driven hydraulic machines can reduce energy consumption by 30-50%, aligning with global initiatives towards greener manufacturing. Coupled with practices such as closed-loop water systems and the use of recycled feedstock, these strategies can help businesses not only meet new regulatory standards but also appeal to the growing consumer demand for eco-friendly products. As the industry moves towards 2025, integrating sustainable practices will be crucial for maintaining competitiveness and fulfilling corporate social responsibilities.

Leveraging Automation and AI to Enhance Efficiency in Injection Molding Processes

As the injection molding industry continues to evolve, leveraging automation and artificial intelligence (AI) has become pivotal in enhancing efficiency and meeting the growing demands of the market. Companies are increasingly investing in smart factories equipped with advanced automation technologies. These facilities streamline production processes, resulting in improved product quality and reduced lead times. For instance, AI-driven solutions can analyze vast amounts of data, ensuring precise monitoring and control of machinery, which ultimately leads to optimized production cycles.

**Tips:**

1. Implement AI analytics to monitor machine performance in real-time, enabling quick responses to any operational issues and minimizing downtime.

2. Invest in automated material handling systems to enhance the efficiency of material supply and logistics within your production facility.

Moreover, as seen in recent discussions among industry experts and academia, the integration of AI not only boosts operational efficiency but also enhances competitiveness in the global market. The shift toward intelligent manufacturing models allows companies to respond swiftly to changes in consumer demand while maintaining cost-effectiveness. This trend is essential for organizations looking to thrive in the fast-paced injection molding landscape of 2025.

**Tips:**

1. Embrace predictive maintenance by utilizing AI technologies, which can foresee potential equipment failures and schedule timely maintenance, thus avoiding unscheduled downtimes.

2. Foster collaborations between academic institutions and industry players to drive innovation and share knowledge on the latest AI advancements specific to injection molding processes.

The Role of Quality Control in Maintaining Trust in Chinese Manufacturing

In today's rapidly evolving manufacturing landscape, the significance of quality control in maintaining trust, particularly within the Chinese manufacturing sector, cannot be overstated. The global market has increasingly recognized that products emerging from China necessitate rigorous quality assurance protocols. According to industry reports, a staggering 70% of international buyers cite quality control as their primary concern when sourcing products from China. This concern is especially critical given the complexities and challenges faced by Chinese manufacturers amidst rising costs and market volatility.

The recent surge in global demand for health functional foods has demonstrated that strict quality management can be a key differentiator. Successful companies emphasize traceability and quality at every stage of the production process, which aligns with consumer expectations for safety and efficacy. Moreover, modern automated techniques are being adopted, contributing not just to efficiency but also significantly enhancing the consistency of product quality. This focus on automation and quality control is particularly pertinent as manufacturers strive to meet sustainability and environmental, social, and governance (ESG) goals, aligning with broader industry trends toward responsible manufacturing.

As the industry continues to evolve, it is essential for manufacturers to adopt and implement innovative quality control strategies to remain competitive and trustworthy in the eyes of global consumers.

Future Trends in Material Science Impacting Injection Molding Techniques

As we move towards 2025, the world of injection molding is set to evolve significantly, primarily driven by advancements in material science. One of the most promising developments is the rise of continuous fiber-reinforced thermoplastics, which are poised to revolutionize the manufacturing landscape, particularly in the automotive sector. The market for these innovative materials is projected to grow from $103.74 million in 2024 to an impressive $146.75 million by 2032, indicating a robust annual growth rate of 4.5%. This surge reflects a growing demand for lightweight, high-strength components that enhance fuel efficiency and overall vehicle performance.

The integration of continuous fiber reinforcement into thermoplastics not only enhances mechanical properties but also enables greater design flexibility in injection molding techniques. Manufacturers must adapt to these changes by adopting more sophisticated molding technologies that can accommodate the unique characteristics of these advanced materials. As we embrace these trends, staying informed about the implications of material science on injection molding will be critical for industry professionals looking to maintain a competitive edge in the evolving manufacturing landscape.

Innovative Strategies for Mastering Injection Molding in the 2025 Industry Landscape - Future Trends in Material Science Impacting Injection Molding Techniques

| Dimension | Current Trends | Future Predictions (2025) | Material Innovations |

|---|---|---|---|

| Sustainability | Increased use of recycled materials | Widespread adoption of biodegradable polymers | Developments in bio-based resins |

| Technology Integration | Use of IoT for real-time monitoring | Advanced predictive maintenance systems | Smart materials with self-healing properties |

| Automation | Increased robotic automation in production | Full automation of low-skill repetitive tasks | Integration of AI for process optimization |

| Quality Control | Use of machine vision systems | Real-time defect detection and analysis | Advanced sensor technologies for feedback loops |

| Customization | On-demand production capabilities | Hyper-personalization in product design | Use of 3D printing for rapid prototyping |