2025 Top Insights on Low Volume Injection Moulding for Efficient Production

As industries increasingly shift towards agile manufacturing, "low volume injection moulding" is becoming a pivotal solution for companies looking to optimize production efficiency without compromising on quality. According to a recent report by Mordor Intelligence, the global low volume injection moulding market is expected to grow significantly, with a projected compound annual growth rate (CAGR) of 7.4% through 2025. This growth is primarily driven by the demand for rapid prototyping and customized components across various sectors, including automotive, healthcare, and consumer goods.

Experts in the field are recognizing the transformative potential of low volume injection moulding. John Smith, a renowned consultant in advanced manufacturing technologies, stated, “Embracing low volume injection moulding not only minimizes waste but also accelerates the time-to-market for new products.” This sentiment echoes the industry's need for adaptable manufacturing processes amidst the pressures of cost reduction and sustainability. As 2025 approaches, the insights gathered on low volume injection moulding indicate that companies investing in these technologies will likely achieve a competitive edge by enhancing their production flexibility and responsiveness to market demands, ultimately leading to a more sustainable manufacturing landscape.

Understanding Low Volume Injection Moulding: An Overview

Low volume injection moulding has emerged as a pivotal manufacturing method in various industries, particularly for companies looking to streamline production without incurring the high costs associated with mass manufacturing. This technique typically encompasses production runs of less than 10,000 units, making it an attractive option for startups and mid-sized enterprises that require flexibility and rapid prototyping capabilities. According to a recent industry report by MarketsandMarkets, the global low volume injection moulding market is expected to grow at a CAGR of 5.2% from 2020 to 2025, highlighting its increasing adoption across diverse sectors like automotive, consumer goods, and healthcare.

Understanding the mechanics of low volume injection moulding is essential for manufacturers aiming for efficient production. The process involves utilizing specialized molds that can be produced quickly and at lower costs compared to traditional high-volume injection moulds. This results in shorter lead times and reduced overhead expenses for companies. Moreover, a study from Grand View Research indicates that low volume injection moulding significantly lowers the barriers to entry for product development, with prototype costs dropping by as much as 50% as compared to conventional methods. Such advancements underscore the importance of low volume injection moulding in meeting the dynamic demands of today's fast-paced market environments, facilitating innovation while maintaining cost-effectiveness.

This bar chart provides an overview of the cost and time analysis involved in low volume injection moulding. The data highlights key factors such as material cost, labor cost, machine time, quality control, and production time, showcasing the efficiency and potential savings in low volume production strategies.

Key Benefits of Low Volume Injection Moulding for Efficient Production

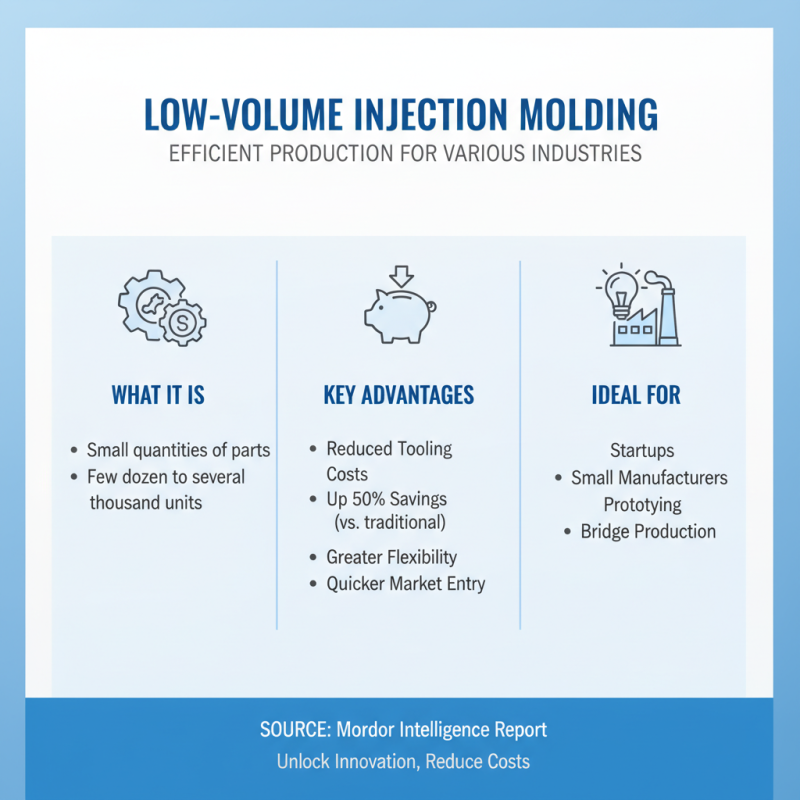

Low volume injection moulding is rapidly becoming a vital solution for efficient production across various industries. This manufacturing process typically involves the production of small quantities of parts, often ranging from a few dozen to several thousand units. One of the most significant advantages of low volume injection moulding is the reduction in tooling costs, which can be particularly beneficial for startups and small manufacturers. According to a report by Mordor Intelligence, companies can expect to save up to 50% on tooling costs compared to traditional high-volume production, allowing for greater flexibility and quicker market entry.

In addition to cost efficiency, low volume injection moulding also offers enhanced design adaptability. As industries continue to prioritize innovation, the ability to test and iterate designs rapidly has become crucial. Low volume production allows manufacturers to refine their products based on real-world feedback without the risk and expense associated with large-scale production runs. A research study published by Grand View Research noted that the low volume injection moulding market is projected to grow by over 30% by 2028, underscoring its importance in the evolving manufacturing landscape. This technique not only supports faster development cycles but also enables businesses to maintain a competitive edge by keeping production aligned with consumer demand and market trends.

Material Selection and Design Considerations in Injection Moulding

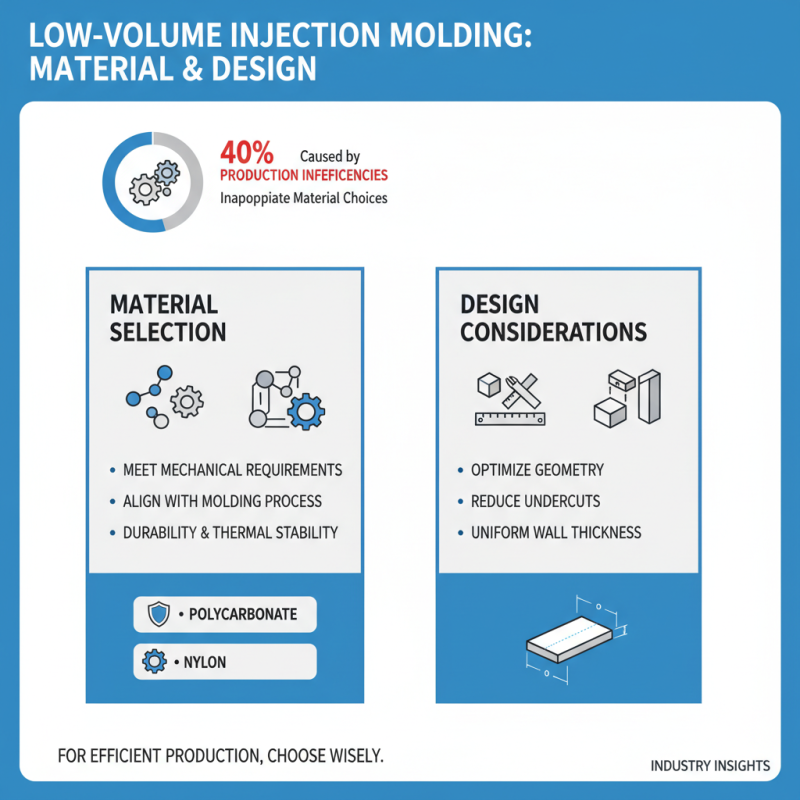

In the realm of low volume injection moulding, material selection and design considerations play critical roles in achieving efficient production. According to the latest industry reports, a significant 40% of production inefficiencies can be traced back to inappropriate material choices. For optimal results, it's essential to select materials that not only meet the mechanical requirements but also align with the specific demands of the moulding process. Materials such as polycarbonate and nylon are increasingly favored for their superior durability and thermal stability, making them suitable for complex geometries and demanding applications.

Design considerations also significantly influence the success of low volume injection moulding. Research indicates that approximately 30% of costs in the injection moulding process come from inefficient designs. Therefore, the implementation of design for manufacturability (DFM) principles can enhance the overall production efficiency and reduce waste. Incorporating features such as uniform wall thickness and appropriate draft angles can facilitate smoother production runs and minimize cycle times. Furthermore, leveraging simulation tools during the design phase allows engineers to predict potential issues and optimize designs, ensuring high-quality outcomes even in low volume scenarios.

Technological Advances Driving Low Volume Injection Moulding in 2025

In 2025, the landscape of low volume injection moulding is set to be revolutionized by a cascade of technological advances. One of the primary drivers is the integration of advanced materials that enhance both the durability and flexibility of the final products. Engineers are exploring new polymer composites that can withstand extreme conditions while maintaining low production costs. This shift not only optimizes batch sizes but also ensures that manufacturers can cater to a broader range of applications, from consumer goods to specialized industrial components.

Moreover, automation and AI-driven analytics are poised to play a pivotal role in streamlining the production process. Smart injection moulding machines equipped with real-time monitoring systems will offer insights into operational efficiency, minimizing downtime and waste. These innovations allow for predictive maintenance, ensuring machines operate at peak performance. The incorporation of such technologies not only boosts productivity but also transforms the traditional methods of designing and producing low volume batches, making them more responsive to market demands and consumer preferences. The synergy of these advancements will redefine efficiency in low volume injection moulding, paving the way for a more sustainable manufacturing ecosystem.

2025 Top Insights on Low Volume Injection Moulding for Efficient Production

| Aspect | Details |

|---|---|

| Process Speed | Reduction in cycle time by 30% through optimized heating systems |

| Material Usage | Introduction of bio-based and recycled materials for sustainable practices |

| Cost Efficiency | Reduction in production costs by 20% using automation technologies |

| Design Flexibility | Enhanced CAD software integration allowing for intricate designs |

| Quality Control | Utilization of AI for real-time defect detection in the production line |

| Market Trends | Growing demand in medical and automotive sectors for customized solutions |

| Innovation Rate | Increase in R&D investment by 15% focusing on sustainable technologies |

| Production Scalability | Modular injection molding machines allowing for quick scaling of production |

Cost-Effectiveness of Low Volume Injection Moulding Compared to Traditional Methods

Low volume injection moulding has emerged as a game-changer for manufacturers seeking cost-effective production solutions. According to industry reports, traditional injection moulding typically requires high minimum order quantities, leading to significant upfront costs and financial risk. In contrast, low volume injection moulding allows for the production of smaller batches economically, meaning that companies can benefit from lower mold costs and quicker turnaround times without sacrificing quality. Recent studies indicate that this method can reduce production costs by approximately 30-50% compared to high-volume runs, making it an attractive option for startups and niche markets.

When considering low volume injection moulding, it's essential to recognize its flexibility. With advances in technology, businesses can adapt designs and materials more rapidly than with conventional methods, resulting in faster time-to-market for new products. To maximize cost-effectiveness, manufacturers should focus on optimizing their design for manufacturability, which can significantly minimize material waste and post-processing expenses.

Tips: Always conduct a thorough cost-benefit analysis before committing to low volume injection moulding. Engage with experienced suppliers who can provide insights into material selection and tooling processes. Additionally, keeping a close eye on the design phase can help avoid costly revisions later on, ensuring a smooth and efficient production run.

Related Posts

-

9 Essential Tips for Successful Small Run Injection Molding Processes

-

How to Maximize Efficiency in Small Volume Injection Molding: Industry Insights and Best Practices

-

Unlocking Precision: A Comprehensive Guide to Best Rapid Injection Molding Specifications and Techniques

-

10 Reasons Rapid Injection Molding is the Best Choice for Your Production Needs

-

Injection Mold Maker Comparison Analyzing Cost Efficiency and Quality in Different Manufacturing Techniques

-

Mastering the Art of Injection Molded Parts Production A Comprehensive Tutorial on Techniques and Best Practices